People spend hundreds of dollars every year on commercially bottled water. People choose bottled water for a variety of reasons including taste, convenience, as a substitute for other beverages, or because of perceived health benefits.

Bottled water is drinking water (e.g., well water, distilled water, mineral water, or spring water) packaged in plastic or glass water bottles. Bottled water may be carbonated or not.

Concerns for health and wellness and the vast improvements in sustainable green packaging are the major factors in driving growth in the global bottled water market. Drinking water source quality around the world has declined in recent years, so optimized filtration systems are becoming more critical in ensuring product quality and consumer safety.

Common challenges with filtration in bottled water production include equipment failure, clogging of filters, and inconsistent product quality.

Filters are used to protect bottled water processes and product quality. They prevent possible contaminants from entering the production system with ingredients. They also remove bacteria and other organisms that might enter the system from a variety of sources, even the environment.

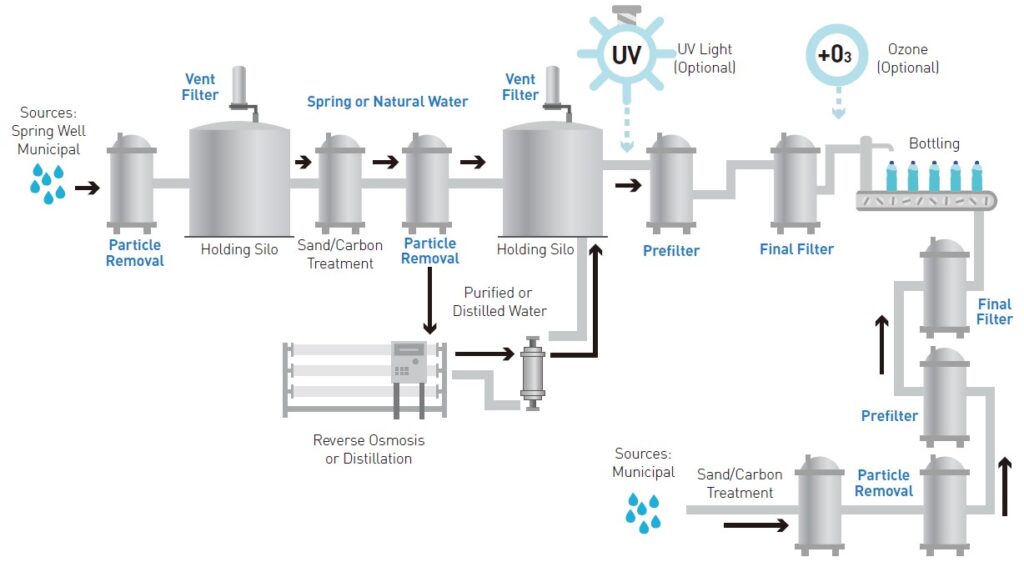

Typical High Purity Water Process

Darlly designs and manufactures filter products that are widely used in the bottled water industry and helps to optimize your manufacturing process. Since 1996, We have expertise in filtration applications in food & beverages and we have supplied more than 4000 customers worldwide.

Depending on the type of bottled water, the filtration steps in the processing of bottled water include:

Darlly products materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations 21CFR, and meet the requirements of European Commission Directives ((EU) 10/2011), and offering for both small scale applications and larger production capacities.

Filtration Solutions for Bottled Water