Food & Beverage is the first priority and rigid demand for people's livelihood. While the sudden outbreak of COVID-19 has made people pay more and more attention to the healthy Food & Beverage industry, the requirements for filtration and purification technology and related regulations have also become stricter.

Darlly Filtration has complete third-party testing reports along with qualification documents, our products are widely used in beer, wine, spirits, bottled water, soft drinks, fruit juice, cold brewed coffee, food and additives, dairy industry and biological fermentation etc. We have dozens of experts and technical service engineers in filtration applications, which can provide customers with comprehensive and timely total filtration solution consulting services at any time.

This leaflet mainly introduces the filtration technology in the wine production process. For other food and beverage filtration solutions such as beer, spirits, coffee etc., please feel free to consult Darlly Filtration Sales Center or your local distributor.

Wine is a kind of alcoholic drinks made from fresh grapes or grape juice through full or partial fermentation which alcohol content is not less than 7.0%. It has a history of thousands of years,"Drink less, but better" is the immortal proverb that wine has been used. There are varieties of wine due to the different grape cultivation time and wine production process conditions.

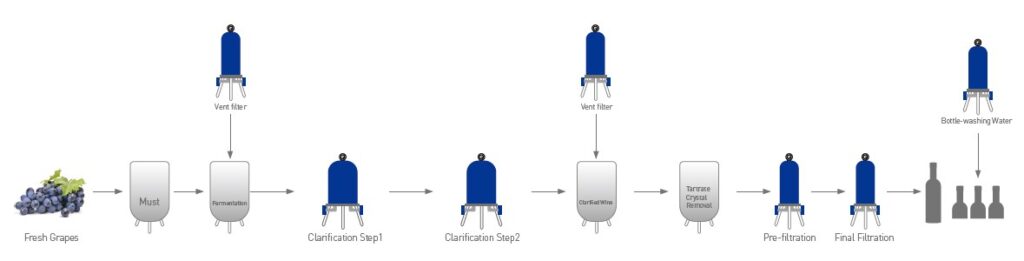

Typical Process Flow for Wine Production

More than 80% of wine is grape juice, followed by alcohol naturally fermented by the sugar in grapes, accounting for 10%-30%, and the rest of the important components are complex,mainly tartaric acid, pectin, minerals and tannins etc.

From grape harvest to wine bottling, there are various processes involved in wine production, filtration technology is an essential part of brewing process. Wine filtration is recommended to use filter cartridges, which can not only ensure the initial fruit flavor and its freshness, but also can avoid spoilage and help extend the shelf life. Bottled wine after filtration is generally more transparent and brighter, purer and clearer which is more favored by the markets and customers.

Wine filtration usually requires multi-step operation, the steps include: