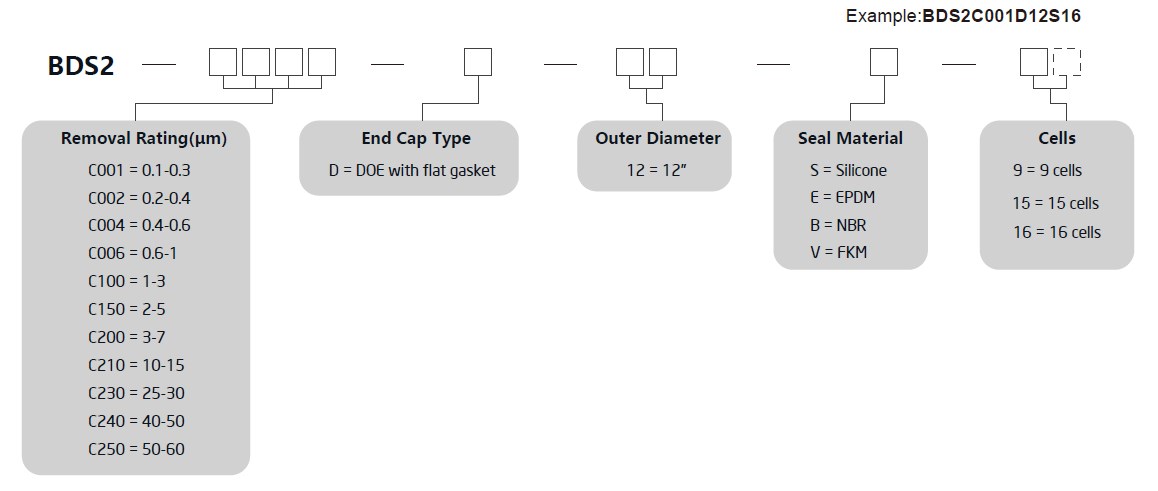

PureDisc™ BDS2 Backflushable Filter Modules

PureDisc™ BDS2 Series Backflushable Filter Modules are new products and designed for repeated backflush applications. The external diversion of the BDS2 has the function of distributing the fluid to each filter plate. The BDS2 ...

PureDisc™ BDS2 Series Backflushable Filter Modules are new products and designed for repeated backflush applications. The external diversion of the BDS2 has the function of distributing the fluid to each filter plate. The BDS2 series modules can be backflushed either with water or product to remove contaminants and prolong their life. BDS2 series modules feature high filtrate quality with higher capacity, reliability, operational advantages, and robustness to meet customer demands and requirements for high-performance products.

| Materials of Construction | |

| Media | Cellulose / Diatomaceous earth / Resins etc. |

| Cage / Support / Diversion | Polypropylene |

| Seal Material Options | Silicone, EPDM, NBR, FKM |

| Dimension | |

| 1m2(10.8ft2)(Φ12", 9cells), 1.7m2(18.3ft2)(Φ12", 15cells), 1.8m2(19.4ft2)(Φ12", 16cells | |

| Operating Conditions | |

| Max. Operating Temperature | 80°C(176°F) |

| Max. Operating DP | 3Bar(43.5psi)@25°C (77°F) 1Bar(14.5psi)@80°C(176°F) |

| SIP(Sterilization in-place) | 125°C, 30min, 3cycles |