Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. It forms a matted or felted sheet on a screen when moisture is removed.

The Pulp & Paper Market has grown significantly in recent years, with an upward trend driven by escalating consumer demand and technical developments. The Paper Pulp Market has experienced a spike in product offers, catering to a variety of demands and interests as sectors embrace innovation.

Challenge

The paper and pulp industry is highly competitive and must total operate cost reduction to meet production needs in the printing, packaging and hygiene sectors. Besides a sudden facility failure has resulted in a line shutdown, and time for restoration is required.

The filtration system can effectively remove and eliminate impurities to protect the pulp and paper production manufacturing machines. It plays a vital role in the filtration system, mainly water filtration, bleach chemical preparation filtration system, coating filtration system, spray system, pulp recycling system, etc.

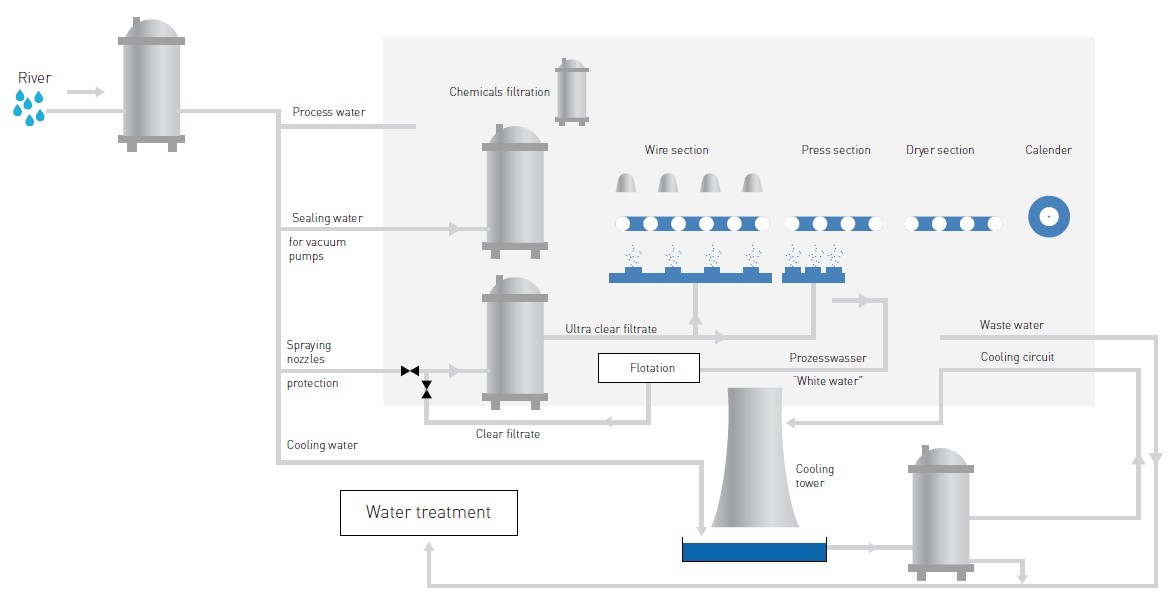

Typical Pulp and Paper Process

Darlly designs and manufactures filter products that are widely used in pulp & paper manufacturing and is dedicated to helping to optimize your manufacturing process. Since 1996, we have expertise in filtration applications in the manufacturing industry and we have supplied more than 4,000 customers worldwide.

Depending on the type of pulp and paper, the filtration steps include:

Filtration Solutions for the Pulp and Paper