Beer is a kind of low-alcohol beverage containing carbon dioxide, which is brewed through grinding, saccharification and fermentation process with wheat malt, barley malt, hops, water as main raw materials. The origin of beer is closely related to grains and has a history of more than 8,000 years. The most primitive beer is made from grain malt, soaked in water, and naturally fermented by yeast in the air.

Beer is rich in nutrients, contains a variety of amino acids, vitamins, low molecular sugars, inorganic salts and enzymes. Low-molecular sugars and amino acids are easily digested and absorbed for human, which can generate huge heat in the body, this is why beer is called liquid bread. However, it should be noted that the amount of beer a person can drink one day is generally no more than 1.2L and excessive drinking may damage cell functions.

Beer can include draft beer, pasteurized beer, fresh beer and special beer according to the production process. In the brewing process of these different kinds of beer, to obtain a high quality, uniquely-flavored and shelf-stable beer, filtration is usually a necessary and essential step. This leaflet mainly discusses the process of beer brewing and its filtration solutions.

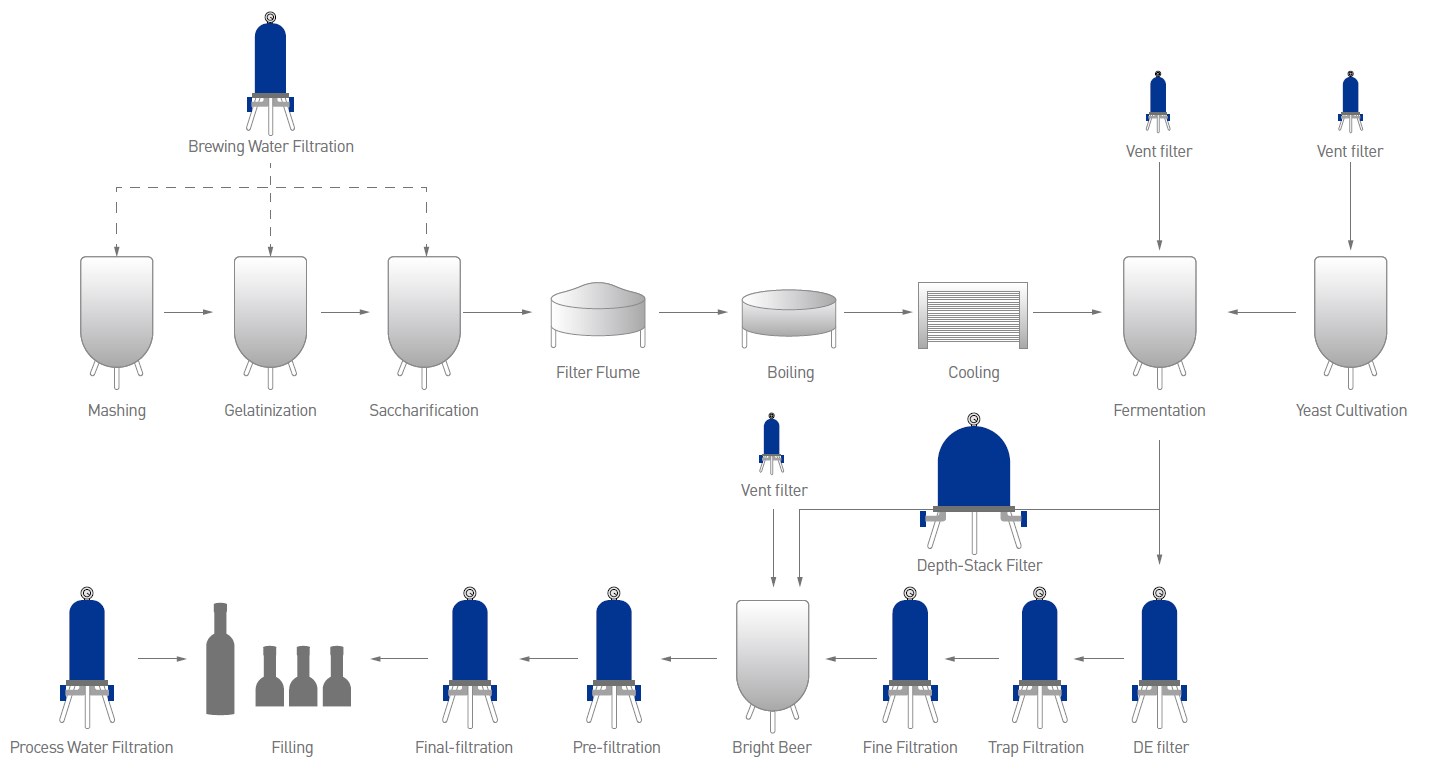

Typical Process Flow for Beer Production

The beer production process is a multi-step operation that includes malt manufacturing, fermentation filtration and filling. Beer brewing generally takes about 1 week to 3 weeks. In filtration process, what beer producers concerned most is probably how to choose flexible, cost-effective and high-efficiency filtration equipment. Darlly as a professional filtration company can provide total filtration solutions for our customers, we have a validation laboratory in Hangzhou, China, dozens of experts and technical engineers are ready to provide comprehensive and timely technical solutions at any time.

Darlly filtration technology industry plays an important role in the beer industry, which can help brewers improving product quality, upgrading production process and controlling microbial impurities.

Darlly all products materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations 21CFR, and meet the requirements of European Commission Directives ((EU) 10/2011), and offering for both small scale applications and larger production capacities.

The main filtration process in beer production include:

Filtration Solutions for Beer Brewing