We consume huge quantities of this increasingly scarce crude oil daily, but reserves are limited. We need alternatives and biodiesel is one such example. In recent years, the competition in the field of new energy technology focuses on biodiesel.

Total global biofuel demand expands by 35,000 MLPY or 20% over 2022-2027 in the main-case forecast. Blending requirements and financial incentives support demand growth in Brazil and Indonesia, China, the United States and Europe, etc.

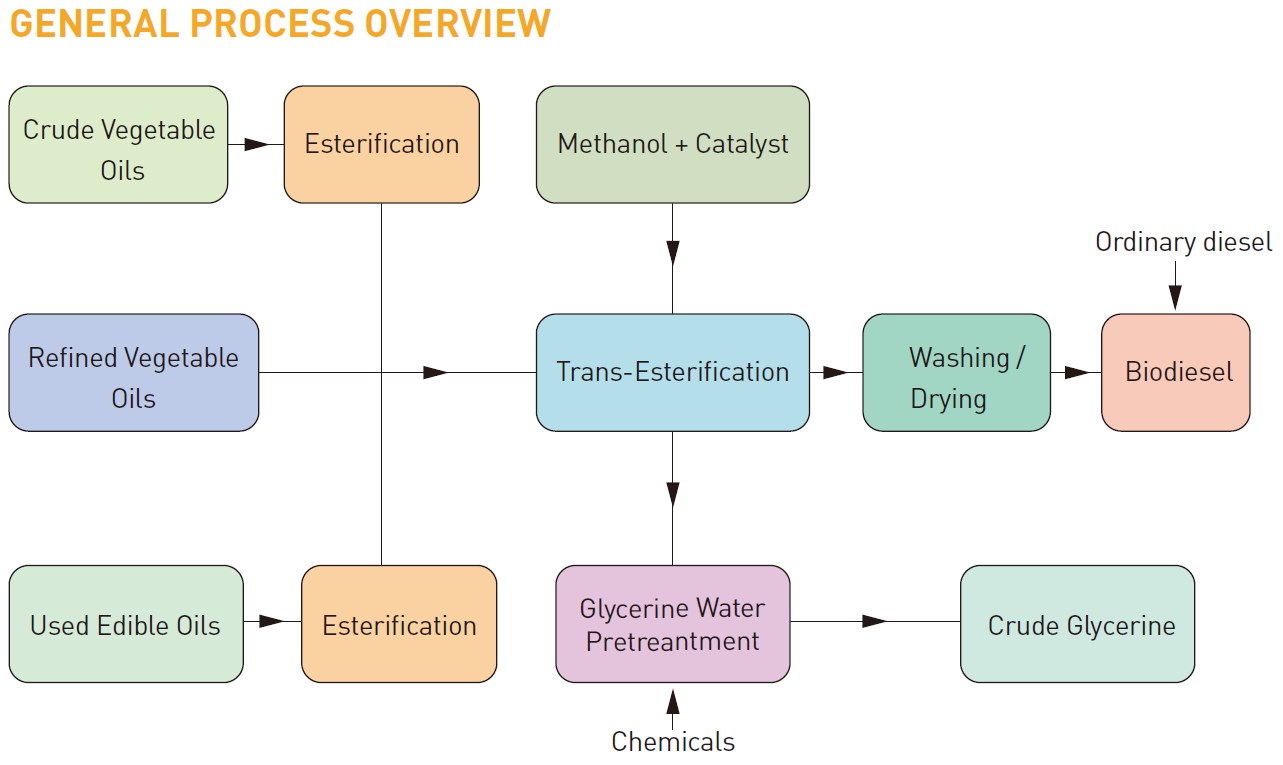

Biodiesel is a renewable, new environmental-friendly biodegradable fuel manufactured domestically from vegetable oils (such as palm oil, corn oil, cottonseed oil, etc.), animal fats (such as lard, butter, sheep oil, etc.), and used edible oils (recycled restaurant grease) in the form of fatty acid methyl ester (FAME), and has long been known as an eventual replacement for petroleum diesel.

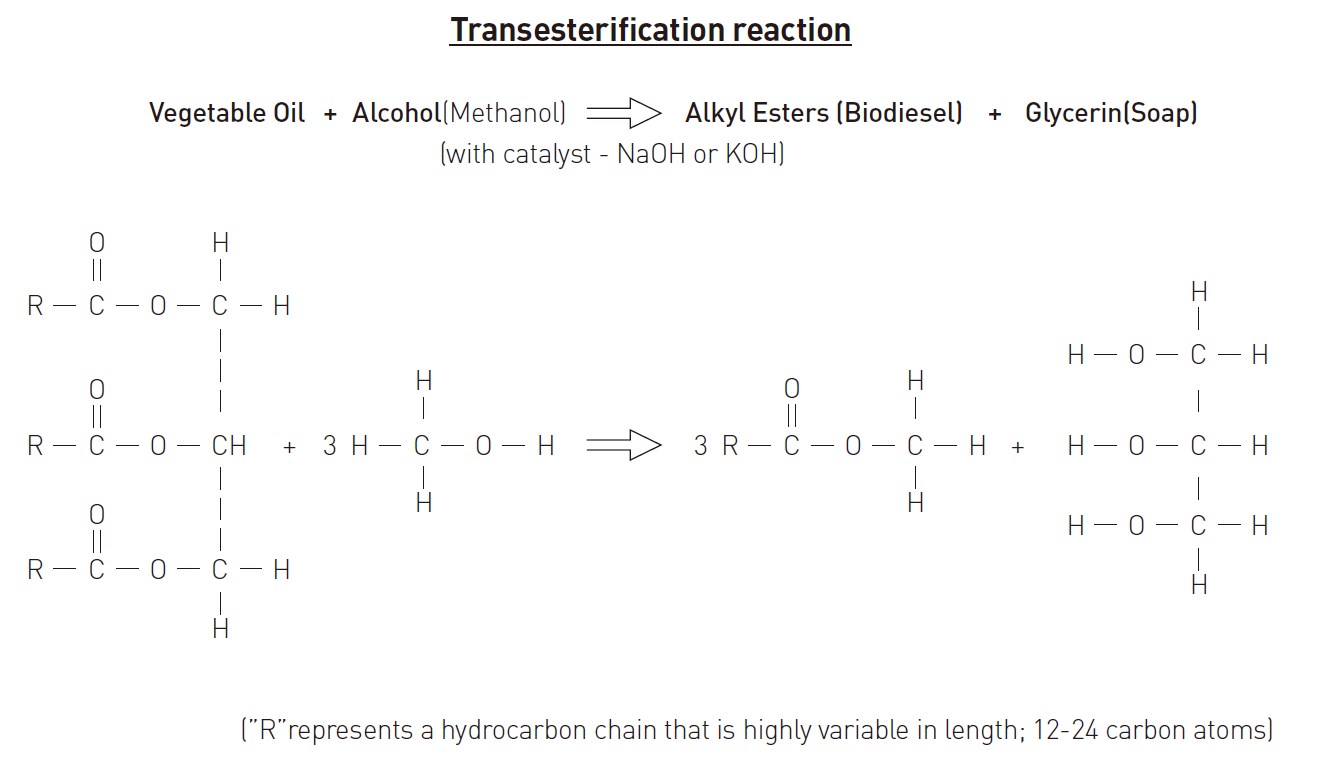

FAME is a mono-alkyl ester produced through a transesterification process, in which triglyceride from the feedstock reacts with methanol in the presence of a catalyst, forming the mixture of fatty acid esters and glycerol (European Biofuels – Technology Platform, 2011).

It is a cleaner-burning, drop-in replacement to petroleum diesel fuel and can be used in vehicles and heating systems. Increasingly stringent environmental policies have made a year-on-year rise in the demand for biodiesel.

The resulting biodiesel contains no sulfur or fossil fuel aromatics. Biodiesel is almost 10% oxygen, making it an oxygenated fuel, which aids combustion in fuel-rich circumstances. Biodiesel can be used pure (B100 biodiesel = 100% biodiesel) or blended (e.g. B10 biodiesel = 10% biodiesel and 90% petroleum diesel).

Darlly Filtration are able to design a complete, high efficiently and cost effectively filtration solution which includes particulate trap filtration and clarification filtration. The solution comprised of:

Our series of filters worked to optimally clean the process feed in stages for the hydrogenation or transesterification process.

Filtration Solutions for Biodiesel Manufacturing