MFF Series Pleated Filter Cartridges

MFF Series Pleated Filter Cartridges are used for filtration of oilfield fluids. Its fully thermal welded construction ensures safe operation and optimum filtration performance. The fully thermal welded construction ensures saf...

MFF Series Pleated Filter Cartridges are used for filtration of oilfield fluids. Its fully thermal welded construction ensures safe operation and optimum filtration performance. The fully thermal welded construction ensures safe usage in filtration with high temperature fluids, acids, diesel, oily water, and solvents. The high performance 3-layers media construction generally have a higher dirt-holding capacity in part due to the more consistent pore size throughout the media with larger filtration area at an absolute rating of beta5000 (99.98% effective efficiency for glass fiber media). As the synthetic fibers are smaller than cellulose fibers, they can be packed tightly together, creating more pores in which to trap and hold particles. Synthetic fibers also perform better in harsh environments that tend to destroy cellulose filters. MFF series is manufactured with a rigid outer cage, ideally suitable for use in harsh oilfield environments and available in a wide range of microns, contributing to the protection of oilfield formations.

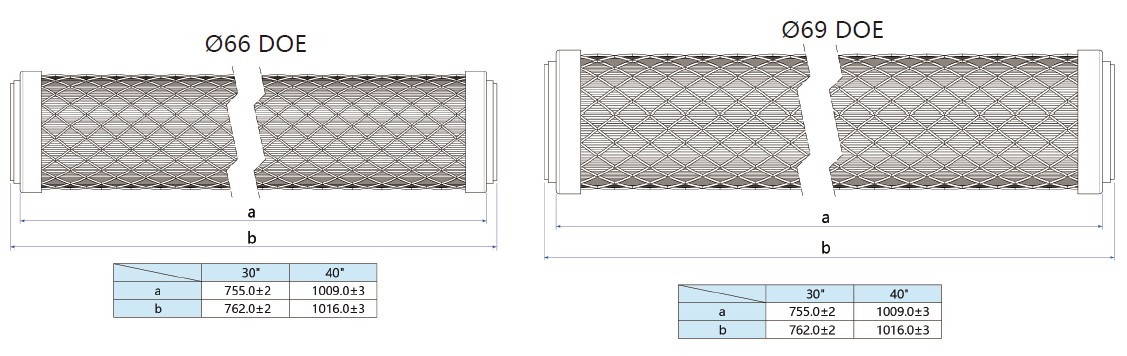

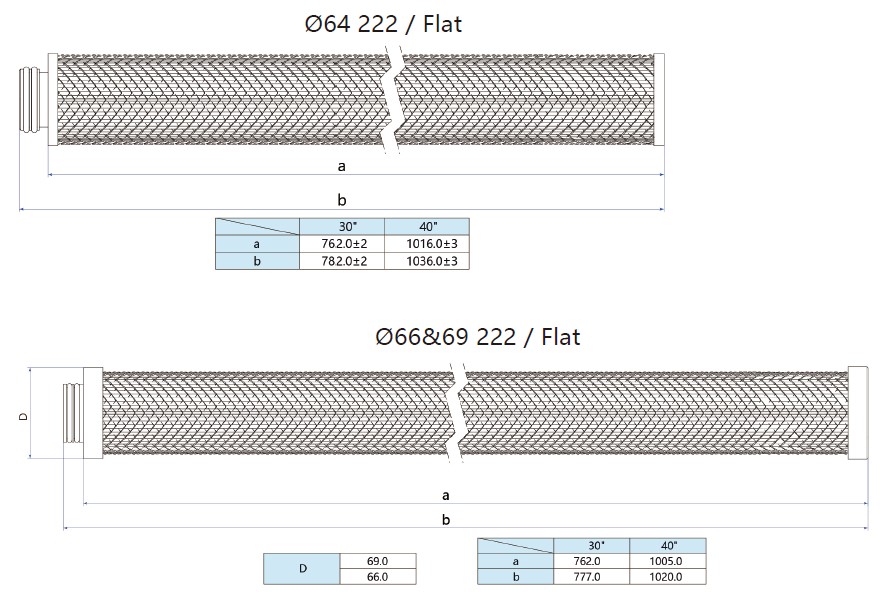

| Dimension | |

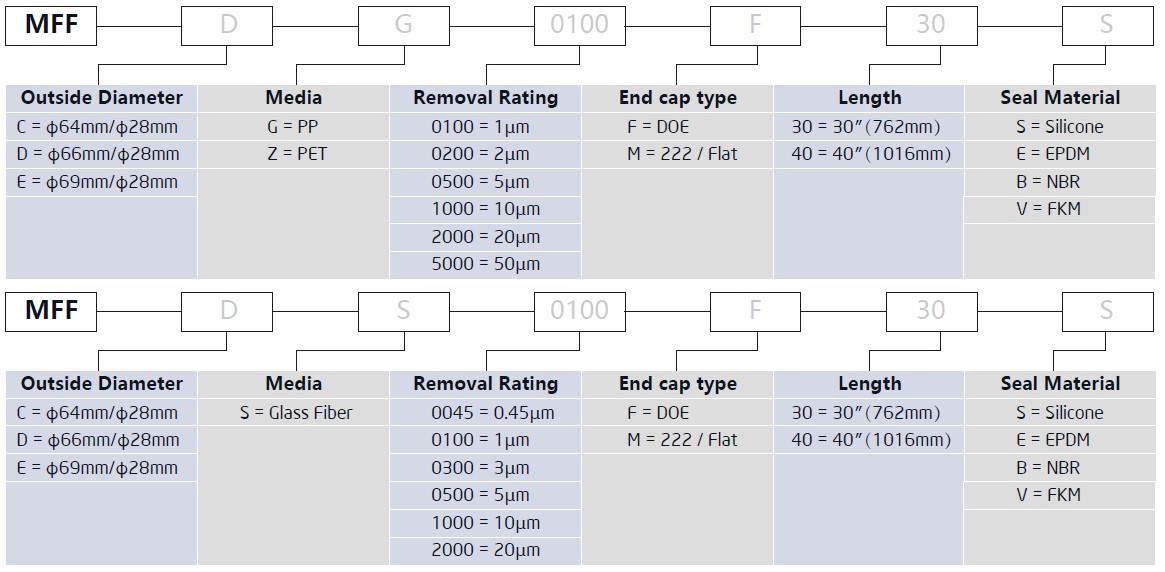

| Outer Diameter | 64mm, 66mm, 69mm |

| Inner Diameter | 28mm |

| Length | 30”, 40” |

| Material of Constructions | |

| Media | PP, PET, Glass Fiber |

| End Cap Material | Polypropylene |

| Center Core | Polypropylene |

| Netting Sealing | PE |

| Sealing | Silicone, EPDM, NBR, FKM |

| End Cap Type | DOE, 222/Flat End |

Operating pressure and temperature: change out differential pressure 35psi(2.5Bar)

Max. working Temperature: 80℃(176℉)

Max. Differential pressure: 5.5 bar(80psi) @ 25℃(77℉) Beta: 5000(99.98% removal efficiency) for glass fiber media Construction: Fully thermal welded