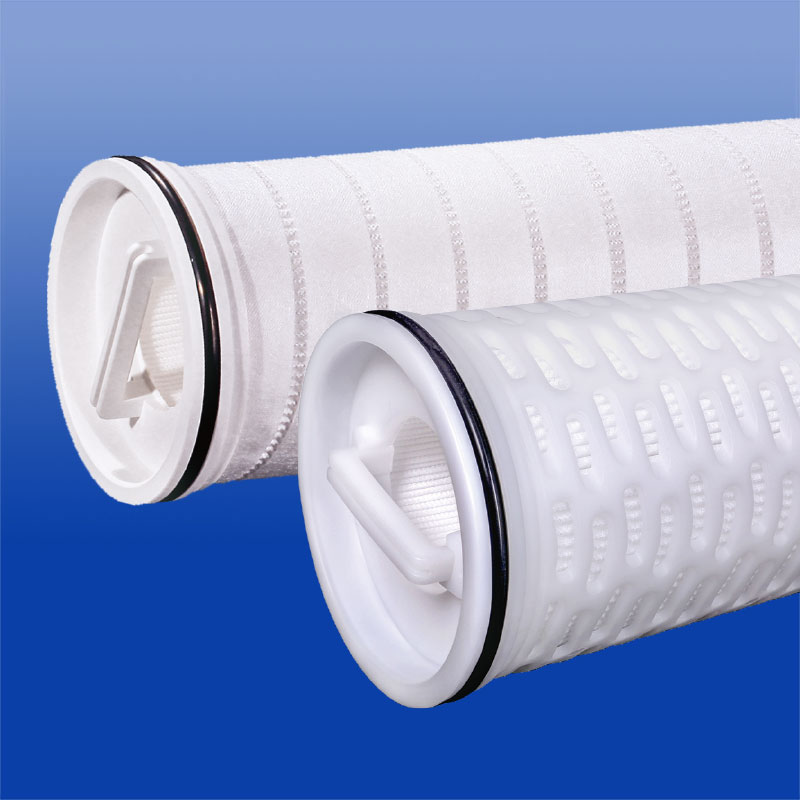

HF Series High Flow Pleated Filter Cartridges

HF Series High Flow Pleated Filter Cartridges are made of depth fine PP non-woven fabrics. The pleated filter cartridge is single open ended and in diameter of 6inch/154mm, inside to outside flow design ensures that the unwante...

HF Series High Flow Pleated Filter Cartridges are made of depth fine PP non-woven fabrics. The pleated filter cartridge is single open ended and in diameter of 6inch/154mm, inside to outside flow design ensures that the unwanted particles are trapped with the element. One HF filter replaces few standard 10" filter cartridges to reduce the operating costs and make change out quickly and easily for critical applications. The multiple layers with depth pleated design provides higher removal efficiency and longer service life than other cartridges of equal efficiency. All the PP configuration with good chemical compatibility ensures that can be used for wide applications.

| Dimension | |

| Outer Diameter | 154mm |

| Length | 20”, 40”, 60”, 80” |

| Material of Constructions | |

| Media | PP, GF |

| Cage/Core/End cap | PP |

| Seal Material Options | Silicone, EPDM, FKM, E-FKM |

| Performance | |

| Max. Operating Temperature | 80℃(176℉) |

| Max. Operating DP | 2.4 Bar(35psi)@20℃(68° F) |

| Recommended Change out DP | 2.2 Ba(32psi)r@20°C(68° F) |