Darlly High Flow filtration system are styled on the design of corrosion resistant FRP pressure vessels.

These provide considerable reduction in capital investment versus stainless steel construction and make use of a quick-acting closure.

Each vessel has the convenience of one filter element that can be exchanged in seconds.

▎Features FRP - GRP housings

Superior chemical compatibility Can withstand higher pressures Ideal solution for highly saline water Lower weight of individual housings allow ease of handling High Flow Housing Capability versus Conventional Filter Housings

Saves time during routine servicing Filter sealing risks can be avoided Less individual cartridge seal points, reduces chance of fluid bypass IMP- Replacements & Damages

Smaller housing minimizes capital expense requirements Reduces system footprint Ease of Use versus conventional Cartridge Filter Housings

No davit arm or tie rod issues to deal with. Easy to set-up by-pass flow connections. Capacity Scaling

Additional housings can be added in parallel to scale-up or scale-down the system flow rate. No need to replace the mounting skid. Adjust System Capacity

To reduce the number of operating housings in the system, remove a Victaulic clamp and install a blind cap. Flexible Design Porting

Ports can be oriented at the installer's preferred orientation for maximum flexibility. Victaulic grooved ends Easy to connect and disconnect with our standard Victaulic style grooved ends Corrosion-Free Construction

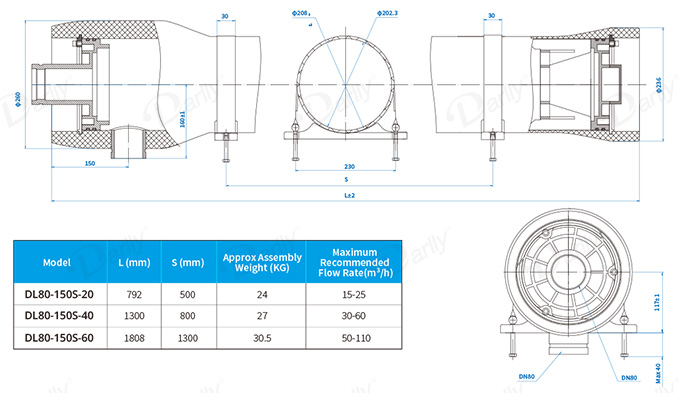

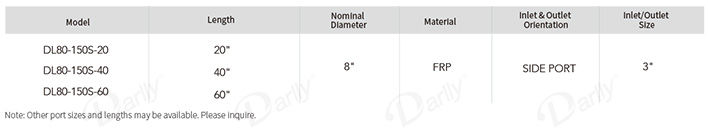

Totally corrosion-free housings, so critically important in cases of highly saline SWRO plants ▎Specification Nominal Diameter 8" Length 20", 40", 60" Material FRP Inlet & Outlet Orientation SIDE POTR Inlet/Outlet Size 3" Maximum Temperature 70°C Maximum Pressure 150psi

▎Applications Desalination Systems Municipal Water Industrial SWRO & BWRO System Pre-filtration Water Process Water / Wastewater & Reclaimed Waters Irrigation Storage tanks for Landscaping Sprinklers Food & Beverage Pre-filtration or Polishing Filtration Oil & Gas Oil/Gas well Injection & Produced Water Chemicals & Petrochemicals Automobile Finishing Electronics Manufacturing Manufacturing of ICs, Memory Drives ▎Dimensions (mm) CataLog